Rudder building. To build the rudder, I needed ribs. These were made from 22g mild steel, bent to a taper. First, I needed a bending break. So I built one. Than, I needed to bend the 15-degree edge on each rib. So, I made a wood-bending block for each rib with proper taper and angle. All in all, I spent about a month figuring all this out and getting materials together. Making each rib turned out to be very easy after all tooling was complete; about a half hour for each.

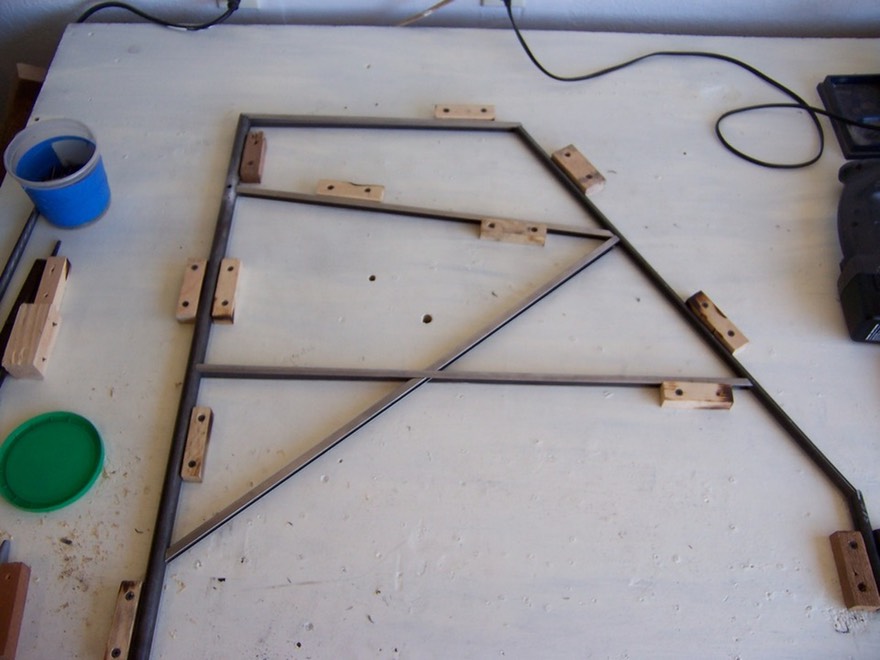

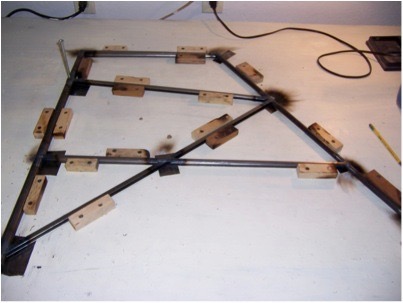

This is the bender I made. 36” long made from angle iron. It works very well and accurate.

This is the wood block for a rudder rib and the layout on the sheet metal. I don’t have a sheer so I have to cut with jig say and that takes some time.

First channel made with new bender. Channel is tapered end to end. 15-degree edge needs to be bent using wood forming blocks.

I made a wood block for the inside of all ribs with the 15-degree bend so the fabric will not sit on sharp edge of rib. Bending was done with a hard rubber hammer to bend each edge. Wood pattern was then slid out of each rib.

Wood pattern block being removed. Note the 15 degree edge.

Here is a better view of the rib with the pattern inside after hammering to shape. All ribs need to be made before construction of the rudder and tail fin can move forward. Tail brace wire attachments need to be made in the vertical stabilizer before welding the ribs in place. The next pictures show the process.

First, hole is drilled according to drawings and washers are made and placed on either side of tube. Washers will be heated, bent, and welded in place to reinforce tail brace attach point.

Washers bent to shape and bolted in place for welding.

Washers welded in place.

Welds cleaned up and sanded.

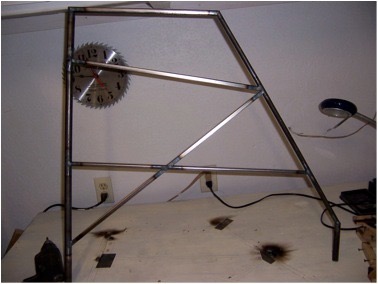

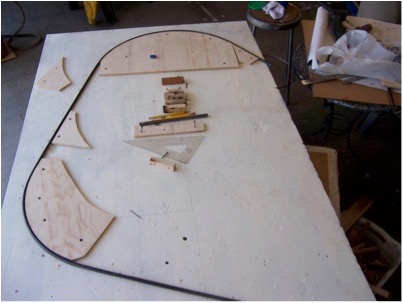

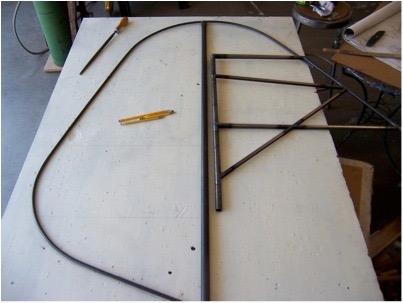

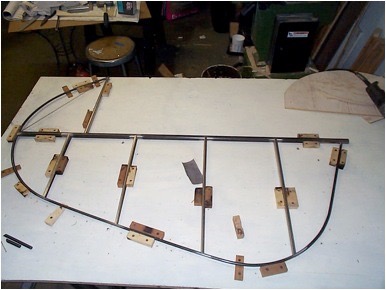

Next, I set up the table and built the tail fin and rudder using the same kind of blocking method used in building the fuselage. The trailing edge of the rudder had to be formed using blocks of plywood to bend to shape. Some heat used but this step was pretty easy.

Here the vertical stabilizer has been tack welded after all parts were blocked to table.

Fin removed from table and finish welded. Rudder next.

Trailing edge being formed around wood pattern. I used some heat on the tube to make the bend.

Fitting rudder with the vertical stab.

Profiling end of each rig to match the vertical tube.

Parts are all fitted together and ready to weld.

Rudder welded and matched to vertical stabilizer.

Return to Past Posts and Pictures by Date